Spanco Articulating Jib Cranes can lift loads around corners and columns, reach into or under machinery and containers, and service virtually any point between the pivot anchor and the far reach of the boom.

These jib cranes support nearly any type of manipulator, balancer, or hoist. Plus, Spanco is the only manufacturer to offer internally piped air in its articulating jib cranes. Our articulating jibs can be mounted on your floor, wall, ceiling, or bridge crane to best suit your needs. These jib cranes support nearly any type of manipulator, balancer, or hoist.

400 Series Bridge-Mounted and Ceiling-Mounted Articulating Jib Cranes

- Offers more headroom and more clearance–both below and above the boom.

- Outstanding headroom permits installation in tight locations, such as low ceilings or crowded shops.

- Bridge-Mounted articulating jib cranes can support nearly any type of manipulator, balancer, or hoist.

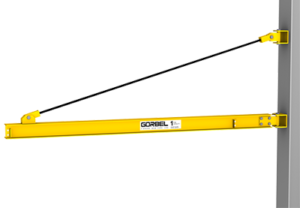

401 Series Wall-Mounted Articulating Jib Cranes

- Offers 360-degree rotation for outer arm and 200-degree rotation for inner arm.

- Perfect for individual workstations where each worker needs complete access to one jib crane.

- Outstanding headroom permits installation in tight locations and crowded shops.

- Provides a clear work area with no floor obstructions and requires minimal overhead clearance for installation.

402 Series Freestanding Articulating Jib Cranes

- Easy installation at nearly any location.

- Offers 360-degree rotation for inner and outer arms.

- Anchor bolts are used to secure the baseplate to a reinforced concrete foundation for ultimate stability under load.

- The pipe mast’s connection to the hexagonal baseplate is reinforced with six equally spaced knee braces.

Options for SPANCO Articulating Jib Cranes

- Electrification (to any device supported on the end of the boom)

- Internal piping (for compressed air within the articulating boom)

- Support for vacuum lifters

- Rotation stops