Overhead Bridge Cranes can be divided into two groups:

Top Running Bridge Cranes, and

Under Running Bridge Cranes (sometimes called under hung).

Top Running Bridge Cranes, and

Under Running Bridge Cranes (sometimes called under hung).

The following will take you through a brief list of topics that should be considered. Please take a brief look and then give us a call, and we can help lead you through the maze to the best cost answer for your material handling needs.

A Bridge Crane system consists of three major components.

the Bridge Crane, which traverses across the runway

the hoist & trolley, which traverses across the bridge and lifts up and down

the runway, which is tied to the building structure.

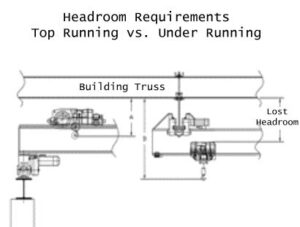

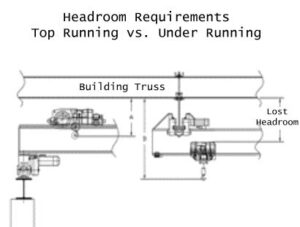

Top Running vs. Under Running is primarily determined by two factors:

The top running configuration is best used in cases where the end user has issues with headroom. The most space efficient configuration is the double girder, top running crane system. When headroom is not an issue a top or under running configuration can be used with either the double or single girder bridge crane.

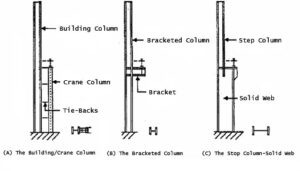

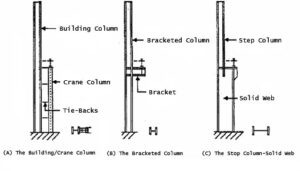

The above figure shows the three primary methods of supporting a top running crane.

The above figure shows a typical support column point.

The above figure shows a typical runway cross section without the crane rail or fasteners. Intermittent welds should not be used in runways subject to fatigue. The picture shows a channel cap on a wide flange section, this is a typical form of a continuous girder.